Dairy

Layer 1

Layer 2

Layer 3

Layer 4

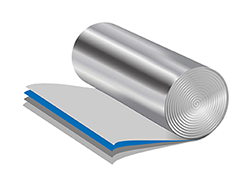

How our substrates are composed

Aluminium

Heat-seal

lacquer

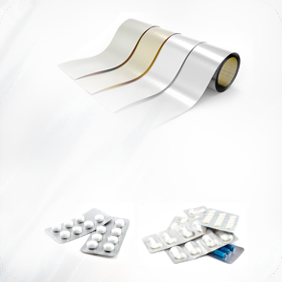

Complete, high quality system for processed cheese: shell foil, lid foil and tear strip

- High performing

- Heat-sealable aluminium packaging

- Tear-tape optional

- Embossed and/or printed designs available

Aluminium

Wax or Glue

Paper

The proven wrapper solution

- Aluminium/paper laminate (wax or glue application)

- Embossed and/or printed designs available

- Rotogravure printing up to 8 colours, multi-side

printing available in one pass

Aluminium

Heat-seal

option

Aluminium lidding. Printed or lacquered. Specific alloy properties for optimum machine running, or laminate options

- Reel-fed material 25 to 50μ aluminium (or laminate structure)

- Embossed and/or printed designs available

- Rotogravure printing up to 8 colours, multi-side

printing available in one pass

Aluminium

Heat-seal

High performing yogurt heat sealing materials

- Reel-fed material (die-cut option available) 25 to 90μ aluminium

- Heat-sealable to PE/PET/PS/PPS

- Standard or proprietary emboss patterns available

- Rotogravure printing up to 8 colours, multi-side printing available in one pass

Aluminium

Wax or Glue

Paper

- Reel-fed aluminium packaging

- Paper/foil laminate

- Unsupported foil gauge starting from 8μ

- Rotogravure printing up to 8 colours, multi-side printing available in one pass

Aluminium

Heat-seal

option

Peel Seal lidding with lacquering or print options

- Heat-sealable foil

- Rotogravure printing up to 8 colours, multi-side printing available in one pass

Aluminium

Adhesive

Paper

Good release and rigidity, and freeze proof laminate structure

- Reel-fed material Aluminium / paper laminate

- Rotogravure printing up to 8 colours